Products & Services

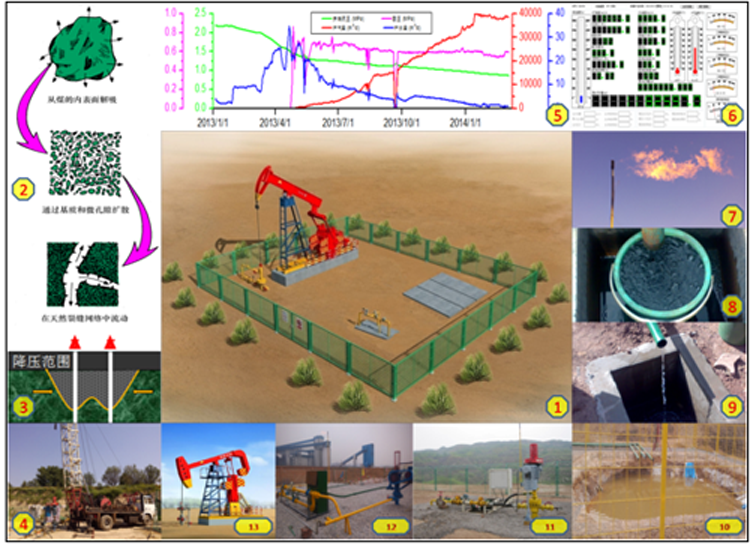

Orion offers equipment and man power required for coal bed methane well pumping; offers site management of production regime and system for coal bed methane well from the life cycle of new well production to shut in well which includes well farm standardization development. Orion could select optimized lifting equipment and achieve low cost and high efficient pumping on the aegis of smart pumping control equipment and based on different geological condition, different types and conditions of wells.

①An outlook of pumping well farm;②methane production mechanism(desorption, diffusion and seepage);③pressure drop funnel(single well control area);④pump inspection operation;⑤production curve diagram;⑥remote control and monitor diagram;⑦produced gas vent diagram;⑧-⑩produced water diagram;⑪-⑬surface pumping equipment diagram

pumping engineering of cbm conventional vertical well and parameter well

pumping of multiple branch horizontal wells of high volume water production and high coal powder production

double cave, multiple layer comingled production of multiple branches horizontal well

pumping of single branch L horizontal well of greater deviation well and big dog-leg degree

directional pumping of 5- section well of depth > 1200m

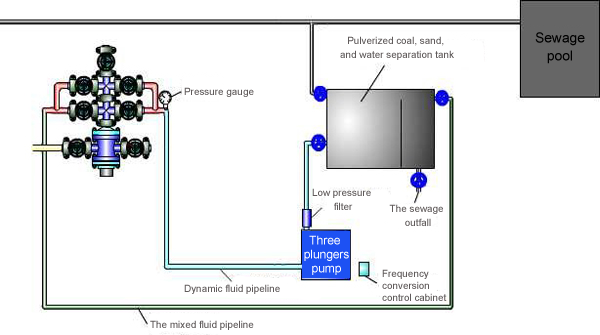

Case of pumping of high coal powder production well

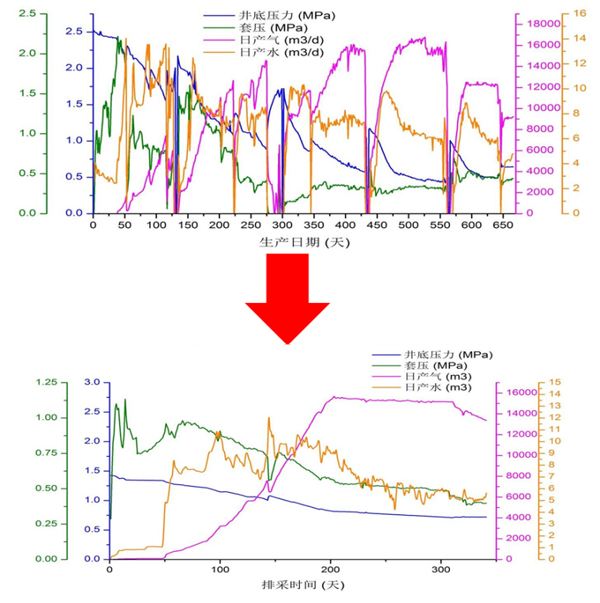

When Orion was pumping at Luliang xxx block in 2013 large amount of coal powder was produced, which was produced in the sag and causing coal bridge that could cover string and cause risk to big pump and thus affect pumping. Orion’s coal bed mmethane well reinjection water system flushes the suction entry and ward off coal powder blocking, it also dilutes coal powder’s concentration and ease risk to damage to the pump. In the end, the well has attained production capacity 15000m3/d.

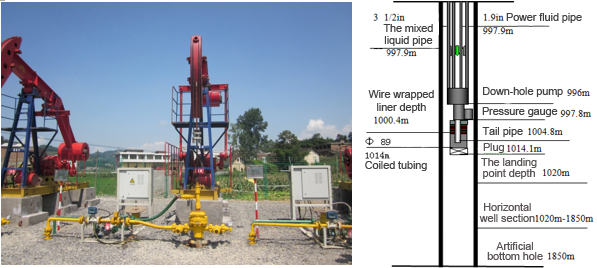

Case of L – shape horizontal well pumping of greater deviation well and big dog-leg degree

Orion has constructed a L-shape horizontal well in Qinshui xxx block in 2013 while conventional rod pump could not run into horizontal landing point and the rod can be abrasive on a side. Orion’s new model hydraulic piston pump has resolved the skewing abrasive issue of the rod thus has extended by far the time between pump inspection and thus maintained smooth production.